Tool Mounting

I mount some tools on some wall

What is this thing?

This is a project I am working on while working at the Makerspace. Recently, we moved a large shelf that held the drills up on the wall. As such, we had to find a new way of holding the drills up on the wall.

This method utilizes French cleats, which is able to hold up individual modules and allow them to be easily adjustable on the wall. There are seperate modules for both the drills, and boxes of drill bits. This page will go into how I made boxes, which was way harder than I expected, which also introduced me to woodworking in general.

Attempt #1

When building a box for drill bits, my coworker suggested that I use box joints to make this box. It would take way longer than using screws, but it would be a good learning experience... right? As such, I started building it with box joints the best way I knew how.

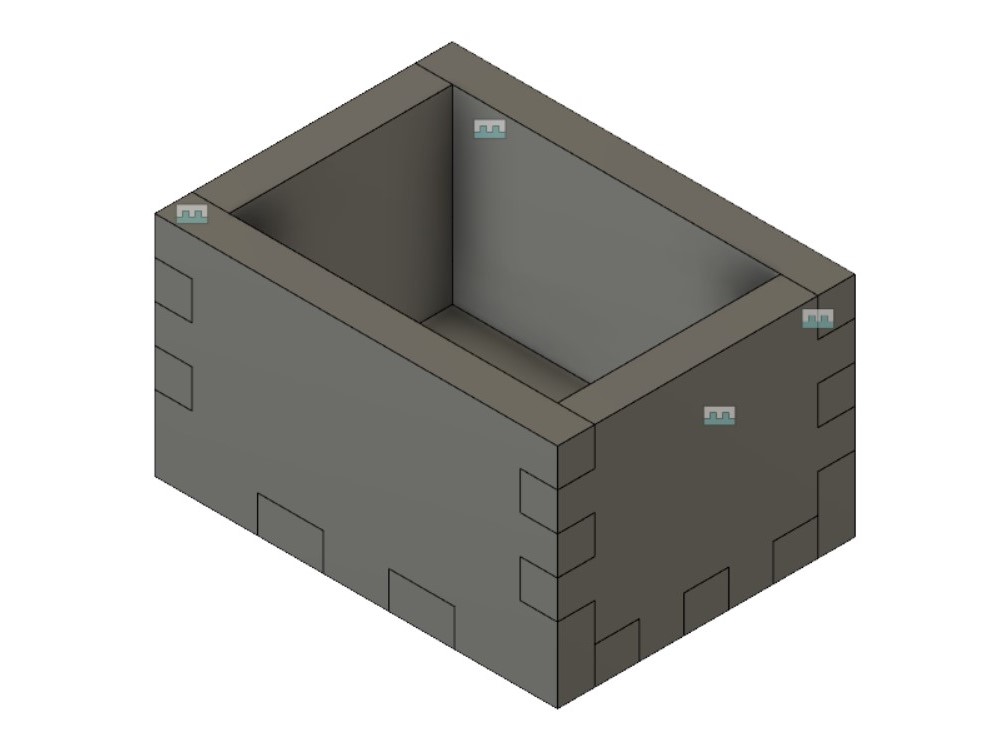

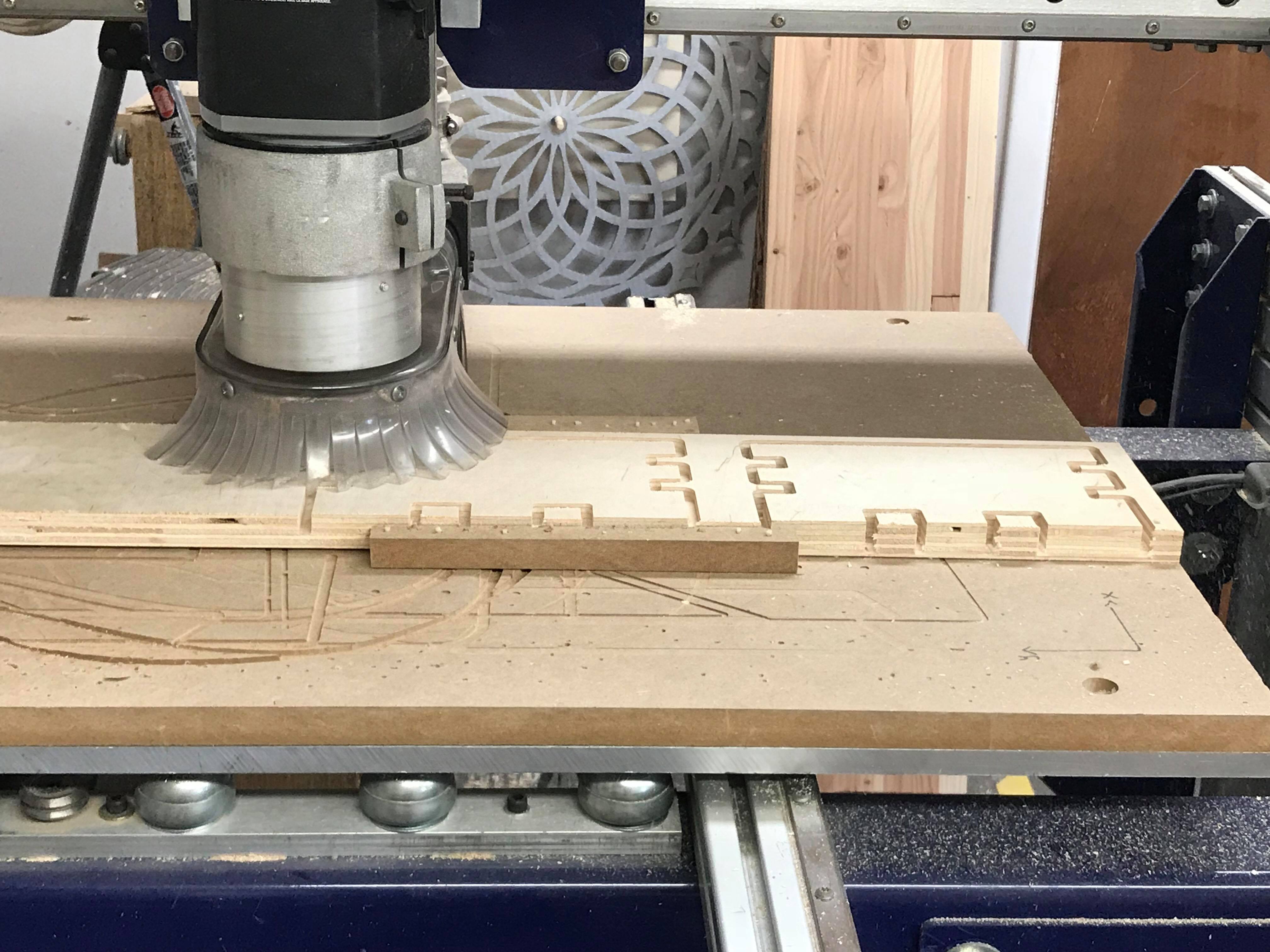

My first attempt was to use Autodesk Fusion 360 to design the box in CAD. I then exported the sketches of each side as a DXF, and imported the file into VCarve to cut on the Shopbot CNC that we have at the Makerspace.

The end result? It came out decently, in that every tab on the joint was evenly spaced. However, due to limitations of a CNC, all of the inside corners were rounded. This made it impossible to fit together on its own, so I had to file a ton. The end box had a lot of gaps from uneven filing, so I am too embarrassed to show it here.

Attempt #2

When my other coworker saw my previous attempt, he immediately started to teach me another method (It must have been quite bad).

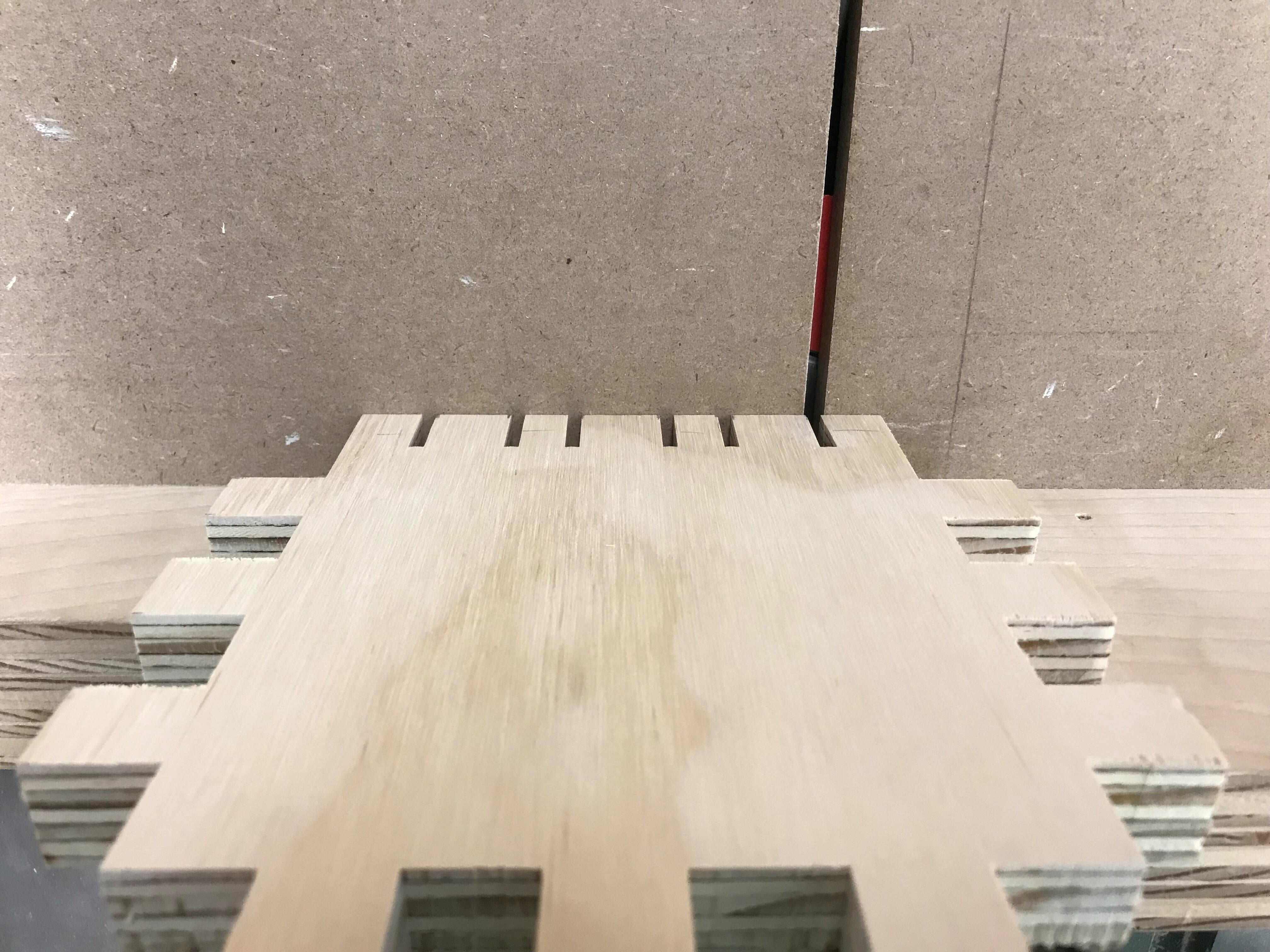

The method he taught me was a more advanced woodworking method, using the table saw (we don't have a box joint jig so this was the method he taught me). I would mark out each tab for the box joint. Then, using a crosscut sled, I would cut along the line of the tab that I had marked out previously.

This was quite a painstaking process that really testing my patience and my back, which got way too sore after leaning over the table saw for hours. After another attempt, I made a box that I think was pretty good for the limited experience that I had for woodworking.

After laser cutting a label and attaching the French cleat, I had a completed module. Not bad, but certainly room for improvement. The table saw is not able to make the tab perfectly level, so there is still some tiny gaps, which are small, but still noticible.

Overall, I had a ton of fun, which was suprising considering it was just a box. I think just being able to learn something, struggle through it, and put it into practice is a very rewarding experience. I am also really thankful to my coworker that is teaching me more advanced woodworking techniques. My next steps for woodworking? Unfortunately, it seems like my coworker wants me to practice more boxes, and then eventually build something that we could demonstrate as an example project for Makerspace. Then, he will show me how to handcut dovetail joints, on a personal project of my own choosing (it really feels like a master-student relationship). I am actually really excited to work on new projects with woodworking, so stay tuned for new projects!